Absolutely a day of ups and downs… so.. let’s start off where the day did.

Having just finished putting the truck back together again, it was time for a really good test drive. This time I picked Hwy 17. A 16 miles windy trek over the 1,814ft. Patchen Pass in the Santa Cruz Mountains (the epicenter of the 1989 World Series Earth Quake, mistakenly associated with San Francisco, 40+ miles to the North).

The old dog handled the mountain with ease. Passing slower vehicles on the steep climb was a non-event. Considering the type of vehicle, it handled the curves quite confidently.

Once in San Jose, first top was Club Auto Sport, where my trainer Isaac has his facility (Fit for Speed). Had a great workout, then headed out into the sun to start running some errands while in The Valley.

First stop was Harbor Freight to check out the finest in Chinese manufactured crap for American consumption.

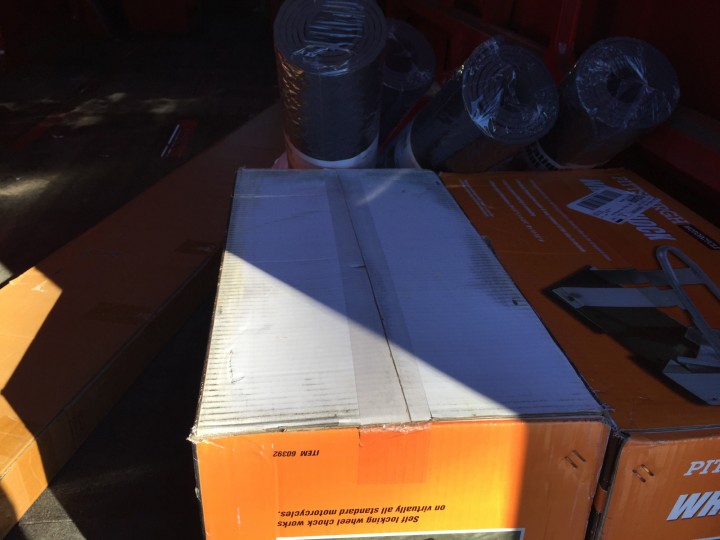

The truck will need a set of wheel chocks, and these were on sale for $40 each, so I grabbed a pair. Don’t know much about them, but hopefully they are not complete crap.

Also needed was some rubber flooring for the back. The original plan (as you might have seen in the previous post) was to carpet all 14′ of the van. After some discussion with some other track junkies I know, a change of specification to rubber flooring was made. This stuff was not very expensive, so I picked up 4 rolls (enough to cover 6′ x 8′) of the stuff on the left ($38 total).

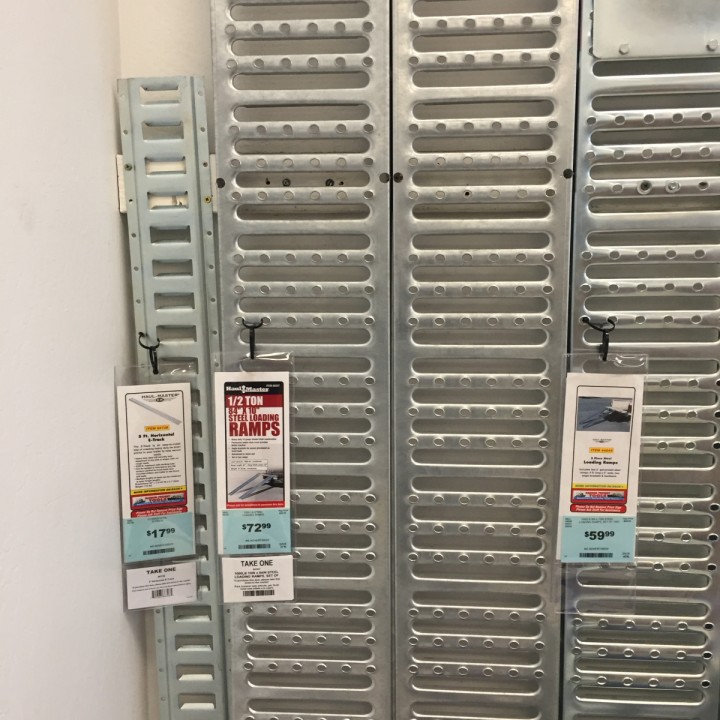

Next up are some ramps. These on the left are 8′ long and rated at 500 lb each. Nothing I own weighs more than that, and made in steel, they seemed stout enough for my purposes. A pair is $72, and that fits the budget nicely.

Ramps, rubber and sundries loaded up and ready for the next stop. However I spent so much time in Harbor Frieght, I needed to get rolling back home to complete some software projects. So.. heading to the dealer for a spare key and the RV shop to look for lighting, will have to wait.

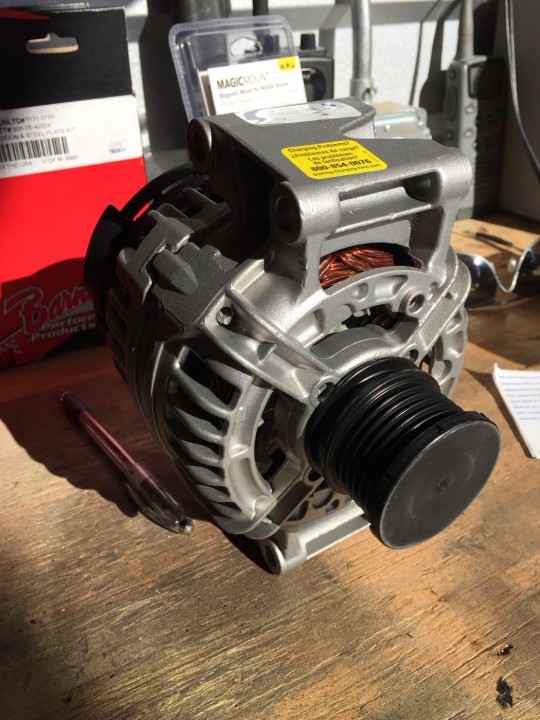

And waiting I would be doing. A lot of it as a matter of fact. Not far out of Los Gatos I began to lose power, followed quickly by a batter light and a vivid reminder of my breakdown on Hwy 1. Recalling how suddenly, and with little warning it died last time, I found the first decent turnoff on the little mountain highway I could find, shut it down and… just felt pretty damn deflated.

Having just a few days before upgraded my insurance policy on the van to something called “Full Roadside Coverage” I ran up my insurance company and for the first time in my 50 years of life, tried out Road Side Assistance.

Very long day/story short.. they dispatched a flat bed heavy-duty tow rig from Santa Cruz, and said that the distance to back to town (about 22 miles) was ALL COVERED. I asked the operator if I could get it towed to my personal shop, and she said I’m covered for up to 26 miles, the distance to the nearest Mercedes Dealership that can service the rig. Excellent (considering I’m getting towed).

The tow truck driver was a nice enough guy. We talked cars and trucks all the way back through the hellish commute traffic (It was 3:00PM by the time we started rolling up the hill). As stated, they transported me all the way to my West Side garage, we unloaded and I put the van way for the next round of repairs.. :/

Unloaded all my stuff from the back….

Then unpacked the ramps to give check out the length and angle.

The deck height on the sprinter is 2′ 3″… which.. is pretty darn low for a vehicle capable of carrying 5000 lb. of cargo. I might have liked to have 10′ ramps, I’m not 100% sure I’m strong enough to reliably get the bike into the truck solo… (perhaps a winch is in my future?). But I’m going to go with these for now. The ramps also have holes in the sides and top that I could use to bring them together and make a nice solid platform for getting two bikes up into the truck, walking along side them.

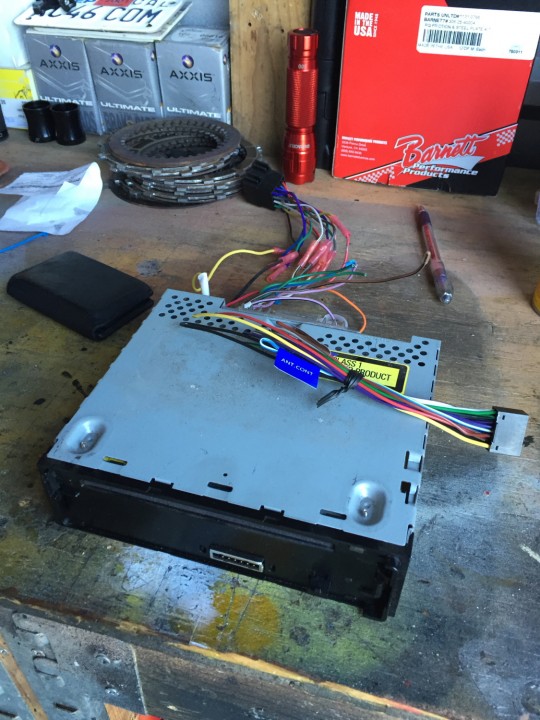

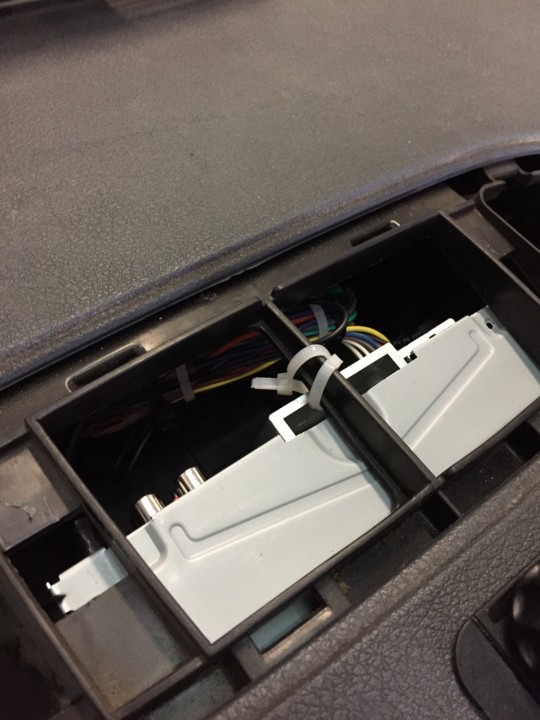

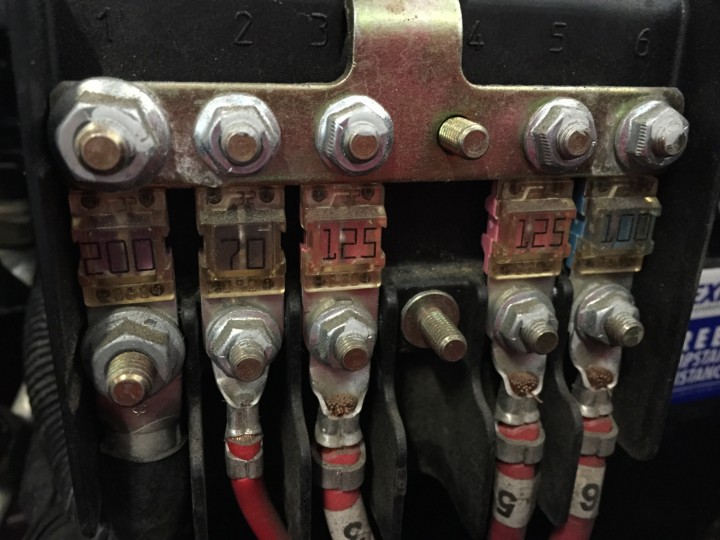

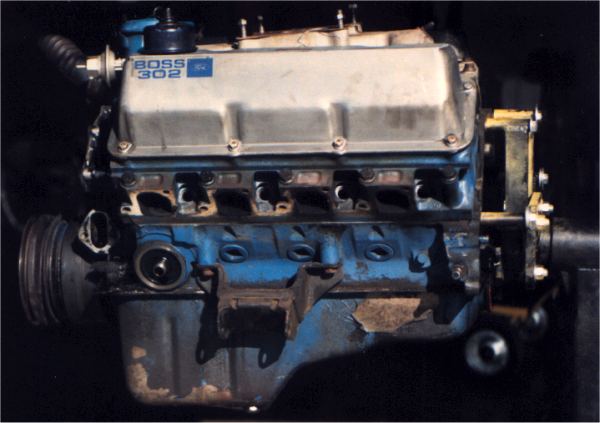

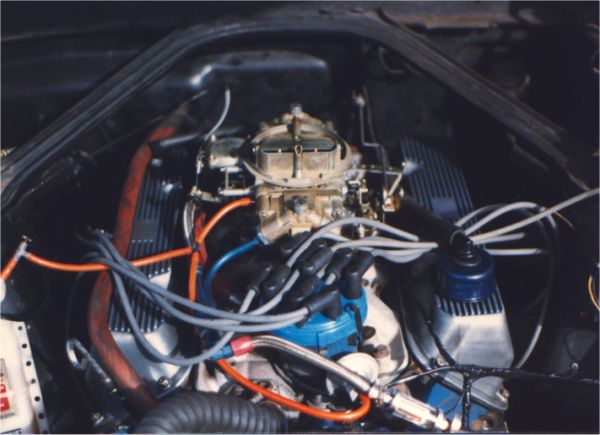

There is a lot more experimentation to do, but for now.. I have to do some research and figure out WHY this things seems to be eating alternators like a kid loose in a candy shop after hours. Something just aint Right.