Looking back at 12 years of blog posts, photographs and tech articles, today I’m pulling up some of my favorite photos from years past.

Photo descriptions include a link to the story where it originally appeared.

Looking back at 12 years of blog posts, photographs and tech articles, today I’m pulling up some of my favorite photos from years past.

Photo descriptions include a link to the story where it originally appeared.

During the US Round of World SuperBike (SBK) Ducati Owners Club, arranged a preview of the Talbot Motorcycle Museum for club members. It was a great, warm and sunny evening in Carmel Valley, amongst some amazing motorcycles!

Here are some photos from the event:

Where you can view these wonderful machines:

The Ducati 749 wore a new suit to the track this time around. Although it looked great, it’s mechanical state was not quite up to to the image. It was more show than go for Sunday’s track day.

The weekend started rough and it went a little downhill from there. While finishing the dress-up on the bike (the red gas tank arrived late on Friday), Saturday, the fuel tank o-ring was damaged and required a fast trip to San Jose to get a $25 replacement o-ring. At least the dealer had it in stock and I was able to get the bike back together in time to pull into Monterey for our pre-track-day dinner.

The first break in my routing was not unloading my truck on arrival. Once back from dinner it was 10:15 PM, I found that someone had pulled up next to me in the space I’d planned to setup my gear. There didn’t seem to be much point in unloading in the paddock at that point, so.. off to sleep I went:

Dawn comes early in Monterey, and despite my original setup plans foiled, equipment was unloaded and the bike was plugged into the generator to start warming up the tires:

With the rest of the crew arriving, we got the bikes into tech.

Dr. Johnny debut his newly refurbished track bike. He’s a happy camper, as you can tell!

Unfortunately, when unloading my 749, I noticed that the bike seemed difficult to move around. After some fiddling around we discovered that one of the front brakes was dragging pretty badly. My first session was going to be spent taking apart the left front caliper.

My pal Isaac was able to score a ride on the damn fine SuperLeggera owned by the track organizer. He was very impressed at the handling.. I guess light

I was eventually able to get the brakes handled and the bike on the track for the last couple of sessions of the day. Things went OK, but it seemed the brake was starting to drag again, so I packed it in; we all loaded up and headed for home.

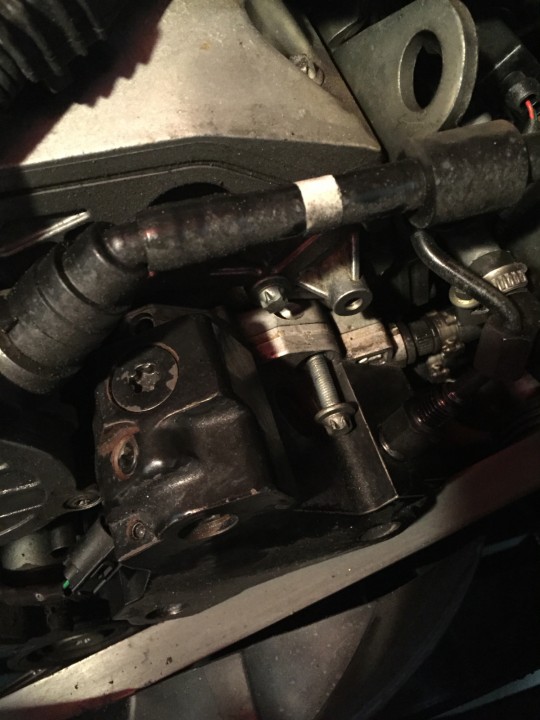

The number 1 suspected cause of the alternator failures, according to the Sprinter People I’ve queried, is a leaking high pressure fuel pump. So, even though I’m not identifying a clear indicator of a problem, it just seemed prudent to take the time to investigate it while everything else was apart.

There were a lot of steps not shown to get to this point. They all seem pretty straight forward, so I’ve skipped ahead to the part where I actually remove the pump.

There are three E10 torx head bolts that secure the pump to the engine block. Two are fairly easy to access and are located on the upper half of the pump assembly.

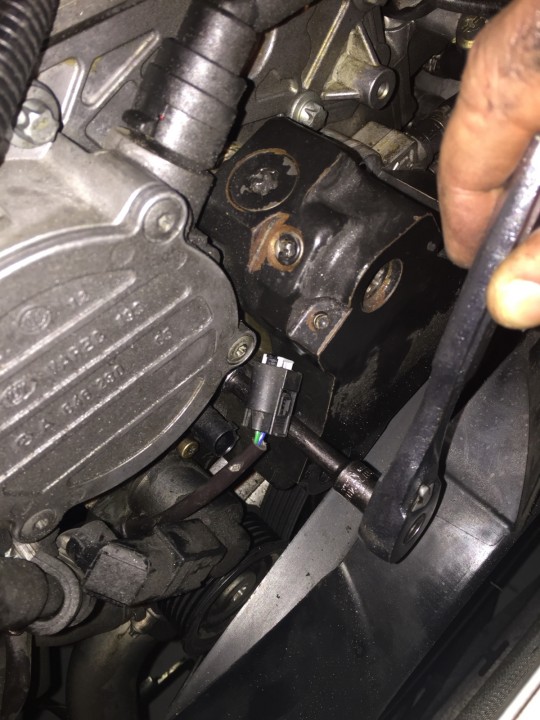

Here is one of the bolts being removed.

The next bolt is located to the left, about mid-pump, very close to the connector you see removed in this photo.

Here is a slightly better angle showing where the bolt is located.

There are two electrical plugs that need to be removed. The one on the right slides out forward. The one on the left slides upwards. The left one is a bit of a pain to removed. I used some channel lock pliers to get an even pressure on the rear clips and gently wiggle it upwards until it came off. Take your time, breaking more parts while doing a repair is not a good plan.

Plugs disconnected and ready to move onto the last steps. NOTE: The high pressure outlet has already been disconnected (top of pump). You can see the threads of the connector at top of photo. To removed these I needed an 18mm open wrench to hold the lower fitting in the pump, and a 14mm flare nut wrench to remove the coupling on the high pressure line feeding the injectors. That’s an important step. You won’t be able to remove the pump with them connected. What I didn’t remove when I was working on mine (maybe a bad choice) were the two lower pressure feed and return lines about mid-pump on the right (not seen here).

Last of the three bolts is bottom center. As much as I’d like to do as little removal of parts as possible, I don’t really see a practical way to get at this bolt without removing the fan blades from the clutch. You just have to do it. I found the 3 bolts on the fan to be 5mm HEX socket (not torx). They were torqued pretty tight. They are a normal right-hand thread, nothing tricky there.

And what did I find on the back of the pump? 2 of the 6 bolts had completely backed out. You can also see that there is diesel fuel on the back of the pump. This matches up with the failure mode described by others, and is the smoking gun (along with the turbo resonator) that I believe was killing my alternators.

All 6 bolts were thread-locked with blue and re-torqued, and pump re-installed.

With the pump re-installed, next step is to re-install the alternator, turbo resonator, intake charge system and get a volt meter installed for diagnostics.

Progress is being made!

While waiting for repair parts, and researching the possible causes for the alternator deaths… I brought over The Boy to help out with some cleanup and conversion prep.

The original flooring was actually in very good shape, other than the poor paint job applied by a previous owner. I set the boy to scrubbing it down with a high-tech degreaser and a lower tech broom. Some of the old loose paint easily came up but the rest seemed adequately adhered for the next step of the project; new flooring.

The rubber flooring I planned to use came in rolls from China, so they had been in that state for a long time. To ease installation when that phase comes around they were unrolled flat and stacked under the plywood floor. Then I found some stuff to stack on top of it to make sure they were reasonably flat.

Back to the headlights… as you can see, the still need a lot of work. This is the 2nd of the pair. Again, it will be treated with sanding and polishing.

The other light is sufficiently refurbished for my needs, and was set aside during the previous day’s efforts. It doesn’t look too bad. But still not perfect. Note: I actually did one more round of this before re-installing them in the van.

Back to the interior work. Getting the road noise levels down is an important part of this projects. If I plan to do long distance treking in this, I don’t want to be yelling all day, or fatigued from the noise. I did test it with an DB meter and the average level was 85db on a highway.

Here the poor-man’s Dynomat is being installed over the wheel wells. This asphalt roof repairing product is reported to have similar sound deadening properties as the vastly more expensive Dynomat. A small roll of this is available at the local hardware box for about $16.

Using a heat gun makes short work of complex curves. Easy-peasy. It’s just a little time consuming to cut the stuff, and press it into place.

The first (and eventually failed) effort to attach the rubber to the wood. In this first round I used a Liquid Nails product. The specs looked good; very low VOCs; water cleanup… what’s not to love?

Placing pressure on the mats then maintaining with some stuff laying around the shop so that it bonds nicely to the floor. At least that was the plan I executed.

Shifting gears a little bit, I removed the Turbo Resonator and examined it on my operating room quality work area. I have a separate write-up on this. In the end I determined that the part was failing and likely contributor to the alternator death syndrome.

Back to the interior. With some help from The Boy we finished covering the wheel wells. The aluminum backed roofing seal didn’t fully cover the wells, so a less expensive product (Jiffy Seal) without the aluminum backing was acquired to complete the product. The Jiffy Seal was then covered with aluminum tape to maintain the same “look”.

One done with the wheel wells, I popped back onto the internet to look at possible causes for the failure, the most ominous of which is a possible failure in the High Pressure injector pump (large black assembly on the right).

It does not look like a fun thing to remove and look for problems. I’m generally of the mind that if it’s not clearly broken or in need of refurbishing, I don’t want to mess with it. Some more investigation is underway.

Below and to the left of the pump is the turbo charger. The intake hose as been removed and the high-pressure cold-side routing, which includes the turbo resonator has also been removed. Both the resonator and the pump are above the alternator and could possible cause it to fail should they leak fuel or high-pressure intake gasses.

High pressure pump in close up. The black part is the front block, which bolts to a larger raw aluminum block with the drive assembly. It’s said that the pump can leak between the two plates if the bolts that hold it together, internally, begin to loosen. This is a known issue with the 2004-2006 model year.

Next effort will be to consider removal of the high pressure pump. At least the front end is mostly stripped down and access will not be horribly difficult.

While doing some research on the problem and waiting for parts, I decided to pull out the headlamps to work on them.

Removed from the truck, they are easier to work on.

One diagnostic task, is to look for unusual current loads in the system. First stop was the headlamps, looking for evidence that some clown hat put in 100w bulbs or some other nonsense. What I found was just that sort of… nonsense. Luckily they didn’t over-watt the lamps, but at some point someone put in those inane blue headlamps (but they looks so cool.. no!). I didn’t detect this because the blue one was burned out. All the better. A pair of 55w H7 replacements will be procured.

With the lamps out, I’m going to do some sanding and polishing on them to return some of the original clarity. Right now, they are much better after that first attempt, but they are not where I want them to be.

Some sanding with 800, 1500 and 2000 grit wet-sand, then a light polish with Mequires… they don’t look too bad. But I know they can be better.

To fully diagnose the electrical gremlins that are plaguing me, getting unrestricted access to all the grounds and the glow plug relay pack, goes a long way. So.. I started to take apart the front bodywork.

Neat Sprinter tidbit… this is the air intake (other side does not have this vent). This is a true cold-air intake. Air box is right there behind the headlamp (or where it would normally reside). Also, it’s possible to get at the grounds behind and under the headlamp with those parts out of the way.

After re-checking and cleaning all the ground table locations, and there are plenty, I focused on the glow plug relay. Typically the relay itself does not fair hideously, but what more commonly happens is a glow plug (or 5) will short out, causing a heavy drain (more than 20A) on the electrical system. 5 glow plugs shorted out is over 100A of current and would easily kill the 90A stock alternator.

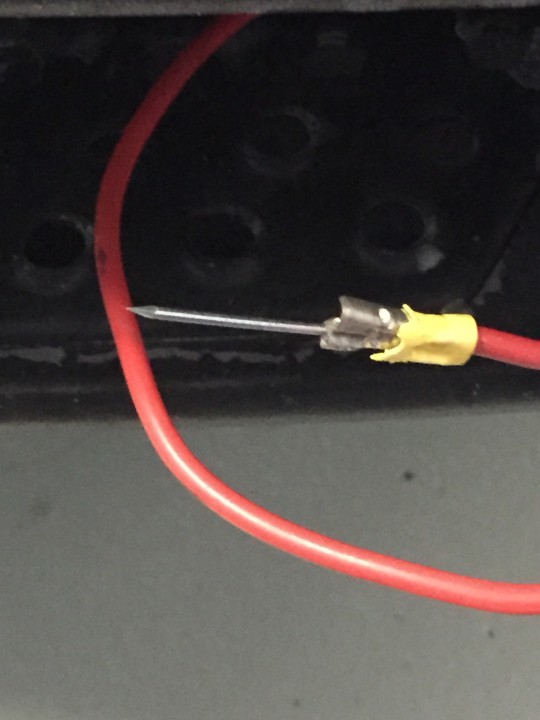

Based on information obtained from the various Sprinter forums, I fabricated (term used loosely) a jumper cable that can be used to test glow plugs for a shorted condition.

Because the simplest place to test it from the glow plug relay harness, I unplued the 5 wire connector (1 for each GP).

On one end of the wire is a spade connector that is screwed to the battery. I didn’t want to have to mess with holding both ends of the wire. On the other end, I crimped on a small finish nail. This is useful when testing the glow plugs from the glow plug harness.

Poking the wire into each of these connectors here, I was able to determine that none of the 5 glow plugs are exhibiting the signs of a short. When I bought the vehicle the owner assured me the glow plugs had all be replaced in the last 2 years. It seems very likely that was a truthy statement. All good in this arena. But that also means I must continue to look for the cause of my woes.

Since the bumper on this thing was in pretty bad cosmetic shape, I decided to remove it too for a little refurbishing at some point down the road.

This little LED light really came in handy when working on things under the beast. Takes 3 C-cells and provides a pretty good amount of light, even if they LEDs are not the wide angle type. It was much easier than the conventional flashlights (due to built-in stand) and not hot and tangly like an old-school drop light (I really do have a heavy dislike for them).

To keep the new battery charged up while I sorted out this mess, I re-purposed one of the 25′ charging cables from the MV Agusta, added the charging lugs to the Sprinter’s battery, and plugged it into this gem I picked up last month. Love having the computerized 1.25 AMP computer controlled charger.

With the Glow Plugs eliminated as the likely cause of my troubles.. the next step is more drastic… checking the turbo system and fuel system components. Good times ahead.

Absolutely a day of ups and downs… so.. let’s start off where the day did.

Having just finished putting the truck back together again, it was time for a really good test drive. This time I picked Hwy 17. A 16 miles windy trek over the 1,814ft. Patchen Pass in the Santa Cruz Mountains (the epicenter of the 1989 World Series Earth Quake, mistakenly associated with San Francisco, 40+ miles to the North).

The old dog handled the mountain with ease. Passing slower vehicles on the steep climb was a non-event. Considering the type of vehicle, it handled the curves quite confidently.

Once in San Jose, first top was Club Auto Sport, where my trainer Isaac has his facility (Fit for Speed). Had a great workout, then headed out into the sun to start running some errands while in The Valley.

First stop was Harbor Freight to check out the finest in Chinese manufactured crap for American consumption.

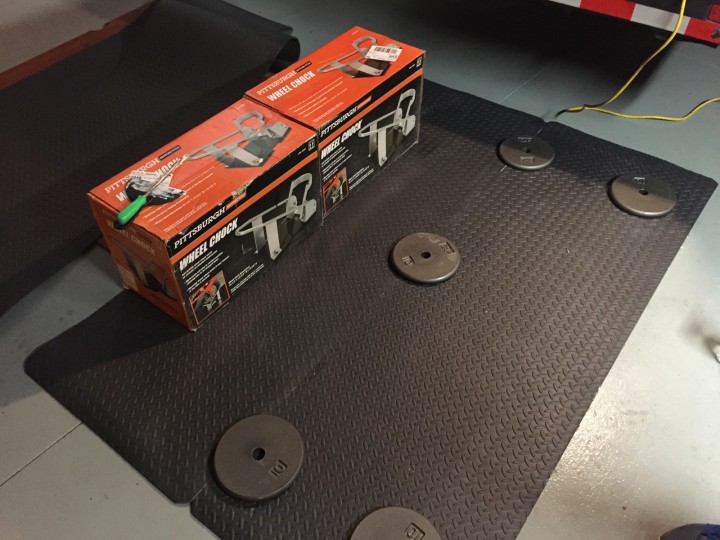

The truck will need a set of wheel chocks, and these were on sale for $40 each, so I grabbed a pair. Don’t know much about them, but hopefully they are not complete crap.

Also needed was some rubber flooring for the back. The original plan (as you might have seen in the previous post) was to carpet all 14′ of the van. After some discussion with some other track junkies I know, a change of specification to rubber flooring was made. This stuff was not very expensive, so I picked up 4 rolls (enough to cover 6′ x 8′) of the stuff on the left ($38 total).

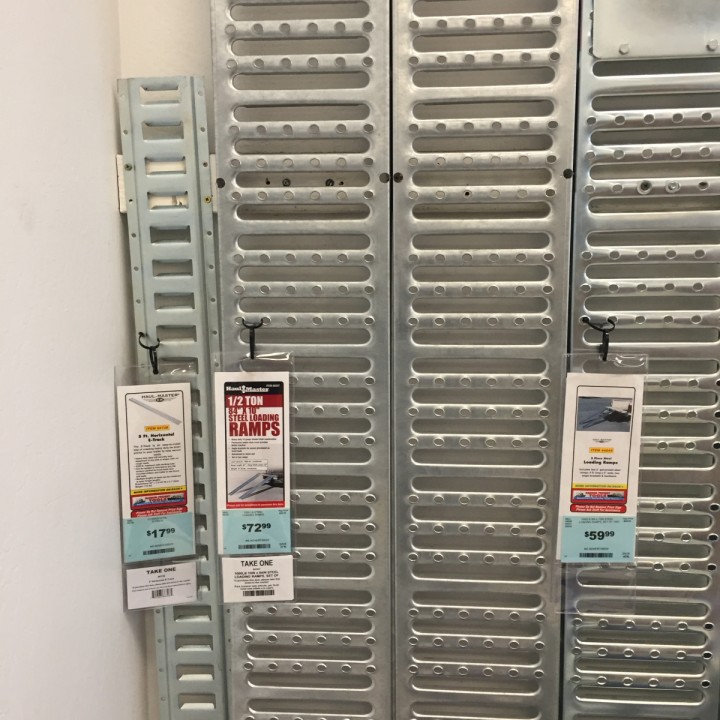

Next up are some ramps. These on the left are 8′ long and rated at 500 lb each. Nothing I own weighs more than that, and made in steel, they seemed stout enough for my purposes. A pair is $72, and that fits the budget nicely.

Ramps, rubber and sundries loaded up and ready for the next stop. However I spent so much time in Harbor Frieght, I needed to get rolling back home to complete some software projects. So.. heading to the dealer for a spare key and the RV shop to look for lighting, will have to wait.

And waiting I would be doing. A lot of it as a matter of fact. Not far out of Los Gatos I began to lose power, followed quickly by a batter light and a vivid reminder of my breakdown on Hwy 1. Recalling how suddenly, and with little warning it died last time, I found the first decent turnoff on the little mountain highway I could find, shut it down and… just felt pretty damn deflated.

Having just a few days before upgraded my insurance policy on the van to something called “Full Roadside Coverage” I ran up my insurance company and for the first time in my 50 years of life, tried out Road Side Assistance.

Very long day/story short.. they dispatched a flat bed heavy-duty tow rig from Santa Cruz, and said that the distance to back to town (about 22 miles) was ALL COVERED. I asked the operator if I could get it towed to my personal shop, and she said I’m covered for up to 26 miles, the distance to the nearest Mercedes Dealership that can service the rig. Excellent (considering I’m getting towed).

The tow truck driver was a nice enough guy. We talked cars and trucks all the way back through the hellish commute traffic (It was 3:00PM by the time we started rolling up the hill). As stated, they transported me all the way to my West Side garage, we unloaded and I put the van way for the next round of repairs.. :/

Unloaded all my stuff from the back….

Then unpacked the ramps to give check out the length and angle.

The deck height on the sprinter is 2′ 3″… which.. is pretty darn low for a vehicle capable of carrying 5000 lb. of cargo. I might have liked to have 10′ ramps, I’m not 100% sure I’m strong enough to reliably get the bike into the truck solo… (perhaps a winch is in my future?). But I’m going to go with these for now. The ramps also have holes in the sides and top that I could use to bring them together and make a nice solid platform for getting two bikes up into the truck, walking along side them.

There is a lot more experimentation to do, but for now.. I have to do some research and figure out WHY this things seems to be eating alternators like a kid loose in a candy shop after hours. Something just aint Right.

Barely, but it does fit. Now to paraphrase Quinn “You’re going to need a bigger garage.”. It would seem so… or external storage lot (there are a few around).

Bought this fancy Magic Eraser thing to try and remove the plethora of hideous graphics on the van. It was $14 at the local auto parts store, I bought both of the ones they had. Sorry, didn’t take a photo of it, yet.

After a few hours of grinding off decals from the driver’s door.. it’s looking just a tiny bit better!

Taking a break from vinyl / decal / sticker removal, I started to measure out the interior of the van for how things are might fit. First was measuring off the back doors to see how far the track bikes will intrude into the cargo area (7′ 6″ minimum). The black line is where it will likely end.

Van has a cargo floor with several anchor points. Good for hauling gear, bad for adding a 2nd seat row as I’m currently planning.

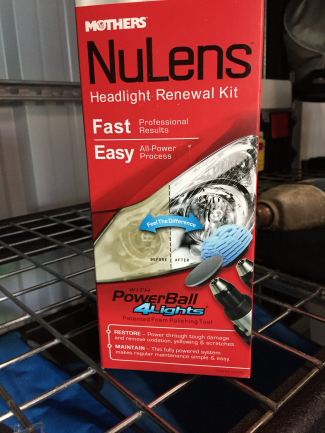

With a lot of 10 year old halogen lighted vehicles, the plastic lenses age, yellow and during into little more than a diffuser. Not good for night time driving. A kit was “On Sale” at a chain auto parts store (I later saw it for the exact same product at another locally owned parts store for the same daily price).

About an hour of sanding on both lights and polishing netted a decent result. I think I need to spend more time working on these lights, it’s still not a like-new effect.

Much more work to be done to bring this thing back to a more presentable condition.

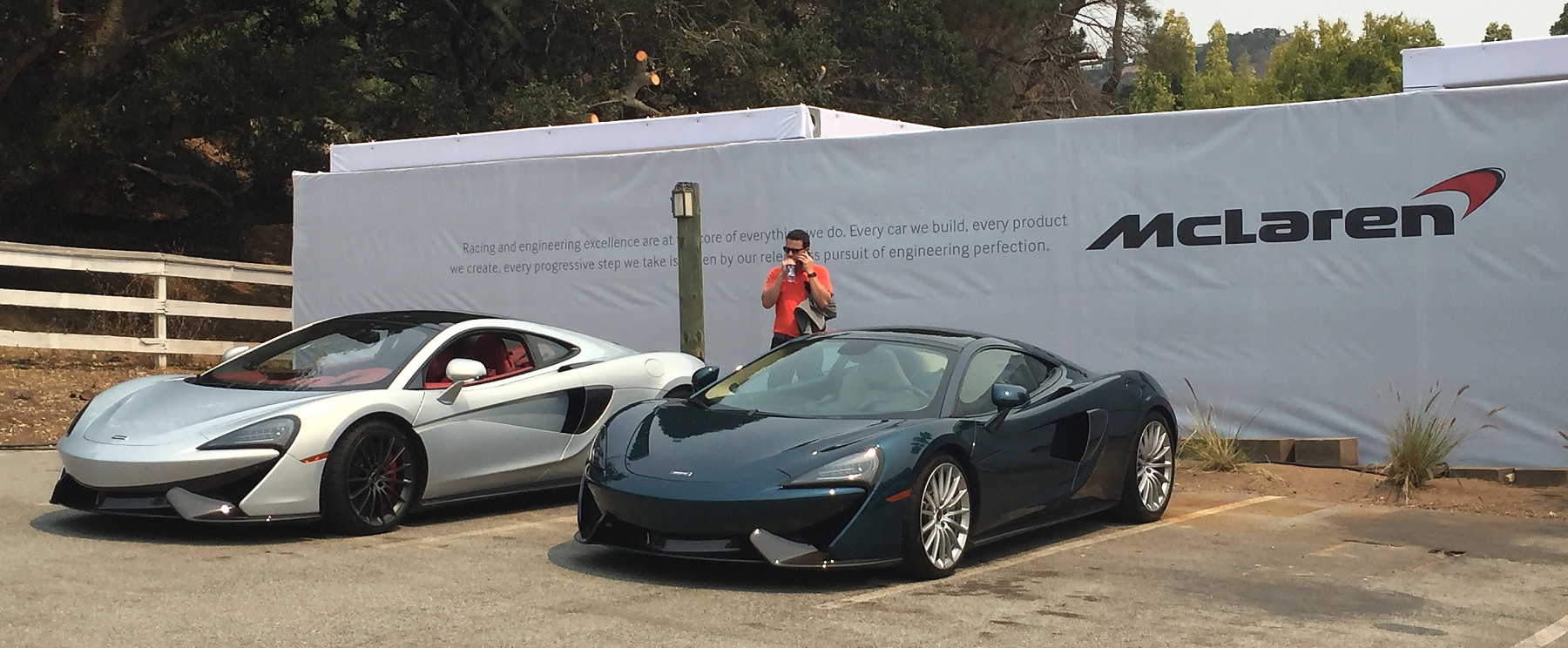

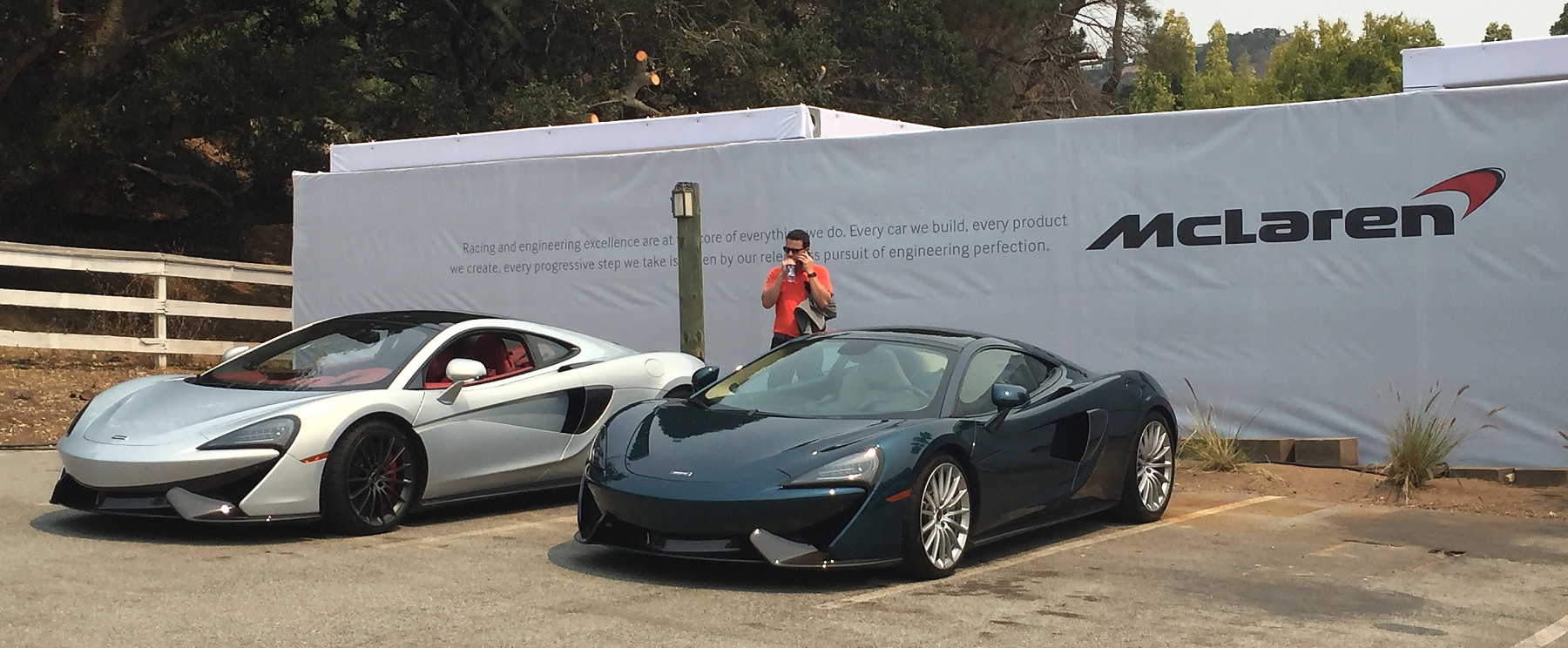

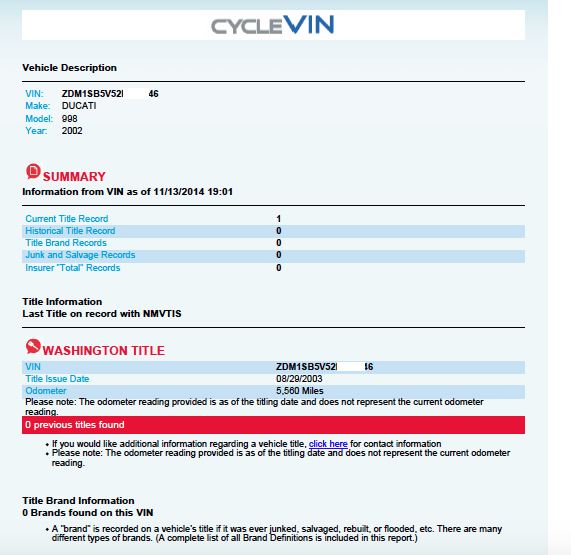

So.. I just lucked upon the VIN number of my first Ducati; a gorgeous yellow 998Mono… here she is on the day I bought her:

2002 Ducati 998 Mono

Termi aftermarket exhaust

HID headlamp upgrade

DP adjustable steering damper

Custom flywheel

VIN: ZDM1SB5V52****46

Yes, it’s been a GREAT many years, but there is a special place in my heart for this girl.. and I’d like to see if I can track here down. We sure had a lot of good times together!:

I’m going to see what I can do to find her. I hope it survived over the years, and maybe I’ll get lucky enough to see her (and maybe own her) again. Only time will time.

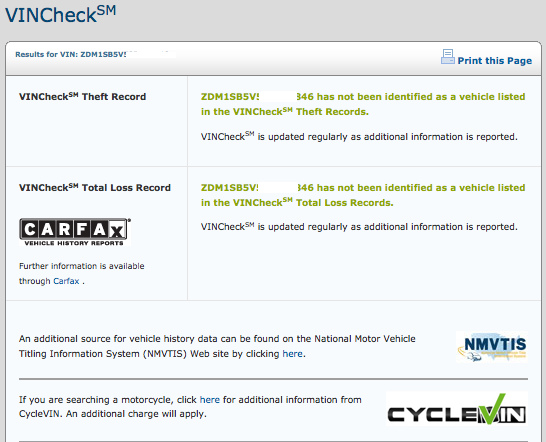

So, looking for something like CarFax for bikes, I found this website https://www.cyclevin.com/ and ran a report. $25.00 later I find the first resale of the bike in 2003, and NOTHING after that! True, they had a record, but it’s basically worthless. 🙁 Lesson learned… technically they provided the info they said they would.. but it’s totally incomplete.

CycleVin BUYER BEWARE!

Stumbled across this site, while looking at some Track Bike posts on Craig’s List. It’s the National Insurance Crime Bureau Running a VIN check on that indicates that the bike has not been reported a stolen or a total loss. More evidence that she’s still out there.. somewhere… waiting to be found.